In the development of automotive electronics, reliability testing is a key part of ensuring that products can operate in a variety of extreme environments.

Recently, the country's many places continue to high temperature, under the severe test of high temperature and high humidity environment, a car screen appeared obvious white dot phenomenon, these white spots not only affect the visual effect of the screen, but also pose a threat to the overall performance of the product.

The screen surface is affixed with a film, and the film is tightly integrated with the adhesive between the film and the glass, while the film itself consists of multiple layers of structures such as AF layer, AR layer and TAC layer, and will next analyze the root cause of this failure phenomenon through a series of professional tests.

1. Optical analysis

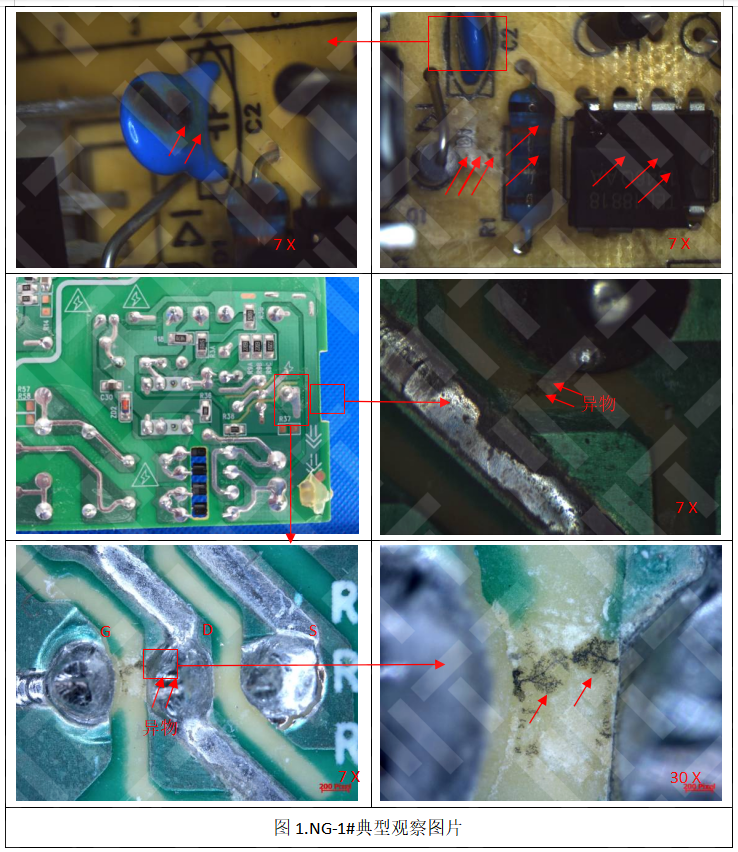

Take the NG screen local optical observation of the white dot position: white dots can be roughly divided into two morphologies: one is more luminous, one is darker and the observation area is marked with a red mark pen.

2. morphological analysis

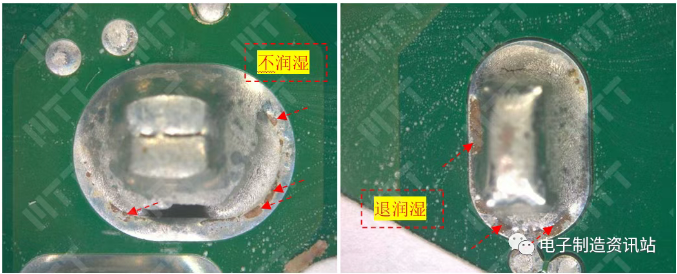

The position of the white dot after the red mark is marked: the shiny white dots are more clear under the electronic imaging, while the dark white spots are blurred under the electronic imaging.

The morphological observation of the shiny white dots: the surface distribution of the shiny white dots has dense particles; the white dots have a clear height difference between the white spot position and the normal position, the white spot position is low, the normal position is high, and the suspected white spot position is dissolved by chemical solvents.

Observe the position of the dark white spot, the surface also has particles, the surface coating local shedding; magnifying the dark white dot and the normal position boundary, the dark white spot surface rough, the position is also lower than the normal position, missing part.

3. Elemental analysis

Analysis of NG screen elements: white dot position mainly contains C, O, Cl, no obvious Si elements; normal position contains C, O, Cl, there is obvious Si; dark position particles of the main elements are in addition to C, O, Si, Cl, but also contain a little bit of Ca.

4. Sliced analysis

Compared with the NG screen white dot position and normal position cross-sectional morphology, the normal position boundary is relatively clear and white, and there is another layer on the outermost layer of the AF layer; the white position boundary is not clear, and the white layer is not obvious.

5. Verification analysis

Take the NG screen part, the optical observation of the tearing film, the surface of the film remains a small amount of glue, whether from the surface or the original surface can be observed in the white dot shape. The white dot position is confirmed in the film layer, and on the surface layer.

6. Verification analysis

In summary, the following conclusions can be drawn:

The reason for the white dots on the screen is that the screen dissolves to varying degrees in the outermost layer (including silicon layer) in , resulting in the visual eye to view the white dot shape. This failure mechanism not only reveals the vulnerability of the automotive screen in extreme environments, but also provides a clear direction for subsequent product improvements.

The high-temperature automotive electronic screen white spot failure analysis not only provides valuable lessons for technicians, but also prompts us to re-examine the reliability of automotive electronic screens in extreme environments. In the future, when developing similar products, we should fully consider the impact of environmental factors on material performance, optimize material selection and process design, and improve the high temperature resistance and overall reliability of the product.。

At the same time, sufficient reliability testing to prevent potential problems in advance is crucial for enterprises. Reliability testing can not only significantly improve the quality and reliability of products, reduce the risk and loss of enterprises, but also effectively improve the user experience and satisfaction, thereby enhancing the competitiveness and market position of enterprises.