In

the field of precision manufacturing, even if it is a seemingly

insignificant assembly cracking problem, every minor defect may become a

major hidden danger of product quality and safety, resulting in tens of

millions of losses. We

found that a stamped copper strip after stamping, in the assembly

process found that there are terminals cracking, cracking has occasional

irregularity. This seemingly ordinary failure is behind the potential

major hidden dangers in the rolling process. This

article will take you to analyze this case in depth, starting from the

cracking phenomenon of the spouse, gradually uncovering the truth about

the surface layering defects of the material, and exploring the reasons

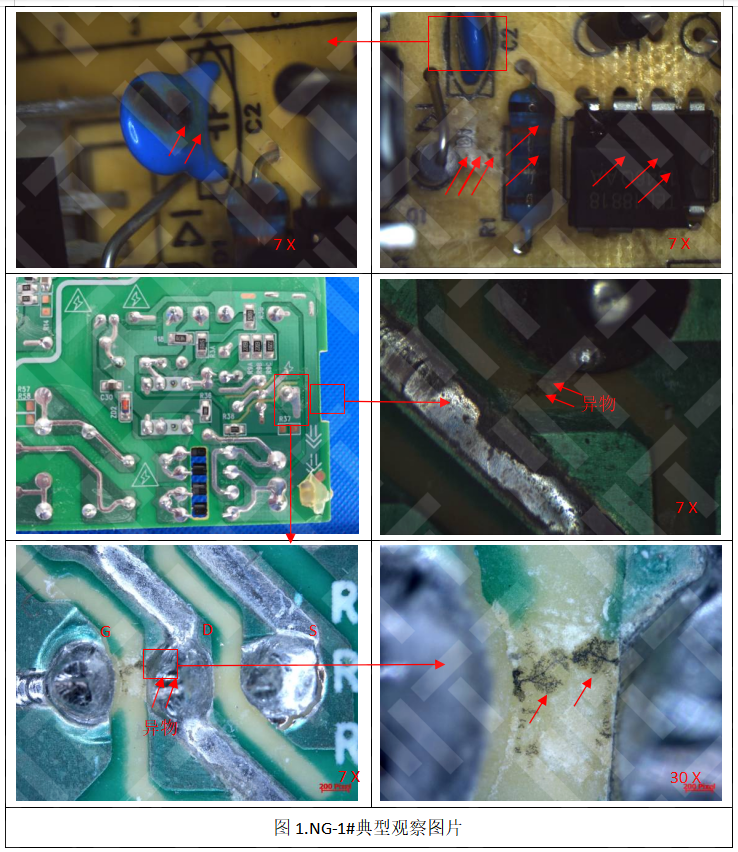

behind it. 1. Low observation. It

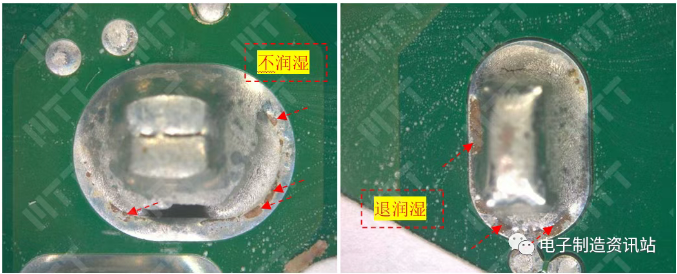

can be seen from the figure that the specimen NG crack is located in

the bending part of the terminal, near the center of the curved arc,

close to the front of the terminal, and the bending part of the crevice

is the most severe position in the bend. The crack has a certain width

and depth, and the crack edges are visible layered gap distribution. 2. Surface analysis The

two edges of the crack have overlapping characteristics, and the

granular tin plateding distribution is visible in the layered gap of the

crack, which indicates that the cracks have existed before the tin

plating. The silhouette of the edge of the crack coincides, indicating

that the crack position is intact before bending, that is, the crack is

caused by bending when punching. Spectroscopic analysis shows that the

local surface Zn content of the coating is high. 3. Metamorphic analysis It

can be seen from the figure that no obvious layering and other defects

have been found at the bending, cracks can be seen at the bending, the

cracks are trapezoidal, and there is no cracking extension at the bottom

of the trap. Before plating Sn, the cracks already existed. The other

crevice can see the "W"-shaped sharp angle, and the "W" sharp angle can

be seen with the overlap contour of the gap, indicating that after the

sharp angle of the crack here is stretched, the original layered gap is

open. Figure

5 shows the gold phase diagram after the corrosion of the specimen. It

can be seen from the figure that the matrix metal phase can be seen in

the distribution of twin crystals, the grain is fine, and the grain

uniformity is better. In the bending deformation area, it can be seen

that the grain is elongated, and the sharp angle area is close to the

outer surface tissue, the core area of the substrate core and the grain

in the uncurved area is still in an equal axis, that is, no more obvious

deformation occurs. 4. Ingredient Analysis & Hardness Analysis Table

1 shows that the chemical composition of the material meets the

requirements of the C2600 grade chemical composition in JIS H3100-2018,

and the cross-section hardness distribution is more uniform.

5. Bending analysis Take

OK samples along the bending process, low observation, as shown in

Figure 6. It can be seen from the figure that the tin-plated layer of

the bending and tensile surface is cracked, and the brass substrate is

exposed. In order to observe whether the substrate is cracked, a

metallographic analysis of the specimen is required. The

metallographic analysis of the bend sample will be bent, as shown in

Figure 6. It can be seen from the figure that the tensile surface matrix

of the bending part does not see the crack, and the compression surface

can be seen to extend the thickness of the belt along the belt, and it

can be seen that the tensile surface has a good extension performance

under a certain bending and curvature when bending the curvature. 6. Discussion and Summary The

study believes that in the plastic deformation stage, copper and copper

alloy grains will be slipping and forming steps, grain orientation,

size is different, the degree of distortion is different, will form

different surface conditions, such as smooth, wrinkles and cracks. It

can be seen from the outline of the edge of the crack, the crack can be

partially coincident, that is, the crack belongs to the external force

to be separated. The metallographic phase can be seen, compared with the

significant plastic deformation of the grain on the surface of the

trapezoidal crack subsurface, the grain of the tissue of the sharp angle

of the trapezoidal crack near the outer surface of the tension is not

significantly elongated, that is, no more obvious plastic deformation

occurs. After the crack subsurface is opened, the crack does not extend

further in the direction of thickness and the bending test can prove

that the material has excellent anti-stretching plastic deformation

ability. The bending structure of the NG specimen has a layering defect,

which is located in the subsurface layer, and the layering is first

broken during the bending process. To

sum up, it can be seen that the defect here is the deep pressure on the

surface of the strip, because the material has excellent plasticity,

the subsequent rolling deformation, the tape extends at the crushing

site, forming a layered defect. Comprehensive analysis can be seen, the material subsurface has a layered defect, is the main reason for the cracks in the bending when the punching.