PCB finished surface in addition to the pad and other areas are covered with welded layer (green oil), its core role is anti-welding short circuit, insulation protection and improve reliability. A batch of PCB in the wave of peak welding after the appearance of green oil blistering abnormal abnormal, individual serious samples of solder diffusion to the welding film lining phenomenon, causing potential circuit failure risk. This paper uses systematic failure analysis to find out the root cause of PCB bonding layer blistering.

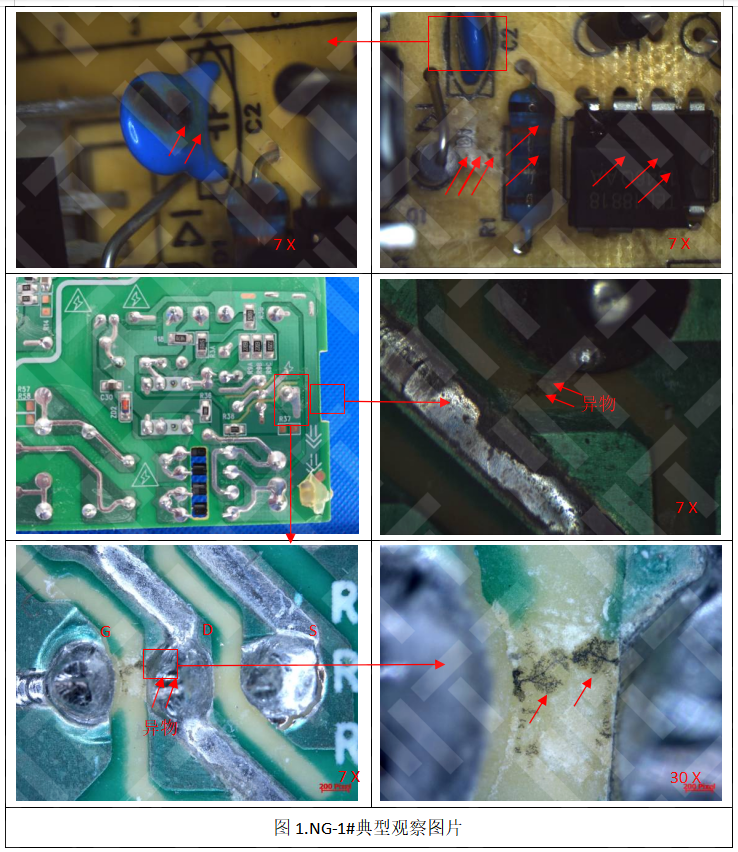

1. Appearance inspection

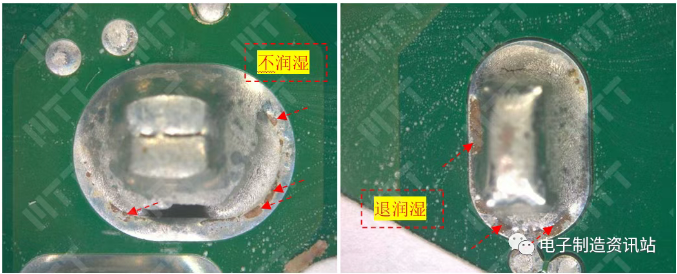

The appearance inspection of the green oil foaming position found that the failure PCBA found that the green oil foaming phenomenon was found in many locations, and the foaming area was mainly located on the copper foil surface around the wave solder joint, and the signs of green oil damage were found in the local position.

2. Profile analysis

After slicing the location of the green oil foaming position, the morphological observation and composition analysis were found, and the solder was found between the green oil and copper foil. The foaming position is complete and the thickness meets the requirements of the industry; the component test results show that no abnormal elements are found in the foaming interface, and the impact of pollution on green oil foam is initially ruled out. In the unbubble area near the foaming area, the interface layering phenomenon is found between the green oil and the copper foil.

3. Copper foil surface morphology observation & green oil adhesion test & thermal stress test

The observation of the surface morphology of the copper foil shows that the turquoise foaming PCBA and the unbubbled PCBA, and the surface appearance of the copper foil is not fundamentally different, that is, the surface roughness of the copper foil is not significantly different.

The results of the green oil adhesion test show that the green oil foamed PCBA, the green oil did not foam the PCBA and the light plate PCB, and no green oil was significantly stripped after the test.

The results of the thermal stress test showed that the light plate PCB was applied in the standard #2 flux, and the green oil foaming phenomenon was also observed 3 times at 288 °C temperature.

The above results show that the green oil foaming has no obvious relationship with the quality of the PCB light plate itself.

4. Flux simulation verification

4.1 Condition 1: Preheating temperature conditions

Pre-heat treatment: PCBs coated with fluxes and uncoated fluxes have not been observed in the stratification of green oil and copper foil after pre-heat treatment.

4.2 Condition 2: Preheating temperature + bleaching 3 times

Preheat + bleaching 3 times: coated into the gray alpha flux and western can Alpha flux PCB, after preheating and bleaching treatment, after preheating and bleaching treatment, solder immersed in green oil and copper foil between the green oil and copper foil. The PCB coated with the Xikkokast flux, after the same heat treatment, found a slight green oil stratification foaming phenomenon. PCBs that are not coated with fluxes, after the same heat treatment, no green oil foam stratification phenomenon was found.

5. Chemical analysis

5.1 FT-IR analysis

FT-IR分析结果显示,成翔阿尔法助焊剂及西可阿尔法助焊剂明显较西可凯斯特助焊剂含有较多丁二酸成分。丁二酸属有机酸,是助焊剂中活性剂,对铜箔表面氧化层具有较强去除作用,起到减小铜箔表面张力,增加润湿力作用。故成翔阿尔法助焊剂及西可阿尔法助焊剂明显较西可凯斯特助焊剂具有较强化学活性。

5.2 GC-MS analysis

The chengxiang alpha flux is close to the C-alpha flux GC-MS spectra and contains C7-C11 alkanes, 1,1,2,3-quamethylcyclohexane, 2-cyclohexane components, and has a relatively short alkane molecular chain. The GC-MS spectrogram of the Xikokaster flux is much different from the former two, containing C10-C16 alkane, tripropyldiol butanyl ether components, containing a relatively long molecular chain of alkane. The shorter alkane molecular chain structure has the characteristics of less chain tangles, strong activity and strong penetration.

6. Discussion and Summary

To sum up, the reason for PCB green oil foaming is: PCB light plate coated with flux, the active ingredients in the flux in the preheating stage, weakened the interface combination of green oil and copper foil, followed by peak high temperature welding, internal stress increased, resulting in the appearance of green oil and copper foil interface layering abnormalities. Chengxiang alpha flux and western cane alpha fluxes contain higher butyric acid active ingredients, and volatile trace components contain relatively short alkane molecular chains, with relatively high activity and permeability, so it is easier to lead to the weakening and stratification of the green oil and copper foil interface.

Summary: The reason for PCB green oil foaming is that the preheating stage of the active flux weakened the combination of the green oil and copper foil interface, and the internal stress increase during the wave welding process, which eventually leads to the appearance of foam layering abnormality between the green oil and the copper foil.